Modern electronics use printed circuit boards to connect components. These boards, often made of flame-retardant FR-4 fibreglass, are key in devices like smartphones and medical gear. They replace messy wiring with copper layers etched into patterns, making devices more efficient and smaller.

Boards are made to different standards. Class 1 boards are for simple items like remote controls. Class 2 boards are for industrial machines that last longer. And Class 3 boards are for critical systems in aerospace or pacemakers, needing to work perfectly under harsh conditions.

The way PCB fundamentals have evolved has changed how devices are made smaller. Modern boards have layers for complex circuits and features to keep them cool. Engineers use special materials for 5G networks, showing how important these boards are for new technology.

The Evolution of Circuit Board Design

The journey from simple electrical systems to today’s advanced PCBs shows how engineering has changed electronics. This change didn’t happen quickly. It was a series of small steps, driven by military needs, industrial demands, and what people wanted.

From Point-to-Point Wiring to Modern PCBs

Early 20th century electrical connections

Before PCBs, people used to solder wire labyrinths by hand to connect devices like radios. These setups were often fragile and prone to failure. A 1925 telephone switchboard had over 900 metres of wiring, showing how inefficient early connections were.

World War II was a turning point. The need for compact, reliable circuits in artillery shells led to changes. By 1948, the US military had standardised printed wiring. This made making circuits 75% faster than before. This change helped consumer electronics grow in the 1950s.

Key Milestones in PCB Development

1943: Paul Eisler’s printed wiring patent

The Austrian inventor Paul Eisler created an etching technique on copper-clad boards. His patent was initially overlooked but later became key for mass-producing circuits. His 1957 BBC television set prototype showed the idea’s worth in the market.

1956: US Army’s automated assembly processes

The US Army’s work on automation led to big improvements. The Auto-Sembly system could make 500 boards an hour. This made electronics cheaper for the public.

1980s: Surface-mount technology revolution

SMT components got rid of wire leads, making smaller circuit boards with more components. The first SMT Walkman (1982) showed how much more could be done in less space than before.

What Is PCB Technology?

Printed circuit board technology is at the core of today’s electronics. It’s the base of everything from smartphones to big machines. It makes sure components can talk to each other well. Let’s dive into what PCB technology is and why it’s key in today’s engineering.

Core Definition and Function

Electrical Interconnection Platform Definition

A printed circuit board is a structured base for electronic components. It’s different from old wiring methods. PCBs have special paths called traces etched on insulators. This makes connections neat and reliable.

Current Conduction vs Signal Routing Functions

PCB traces have two main jobs. Current conduction is for power, using thick copper paths. Signal routing is for data, using thin traces. This is key for devices like Wi-Fi routers.

Fundamental PCB Characteristics

Multi-Layer Construction Principles

Complex devices use multi-layer PCB construction. They have 4 to 12+ layers stacked. Server motherboards are a great example, with layers for power, ground, and signals. Vias, tiny holes, connect layers without interference.

Standardised Copper Thickness Measurements

Copper thickness affects how much current a PCB can handle. Here are some common standards:

- 1 oz/sq ft (35 µm): Low-power devices

- 2 oz/sq ft (70 µm): Cars and control units

- 3 oz/sq ft (105 µm): Heavy-duty equipment

Dielectric Material Properties

The insulating substrate’s dielectric materials are very important. FR-4 fibreglass is used in most PCBs. It has:

| Property | Value | Significance |

|---|---|---|

| Thermal Resistance | 130–140°C | Prevents warping during soldering |

| Dielectric Constant | 4.3–4.9 | Maintains signal speed |

| Flame Retardancy | UL94 V-0 Rating | Meets safety standards |

For high-speed needs, like 5G, special substrates like Rogers 4350B are used. They help keep signals strong.

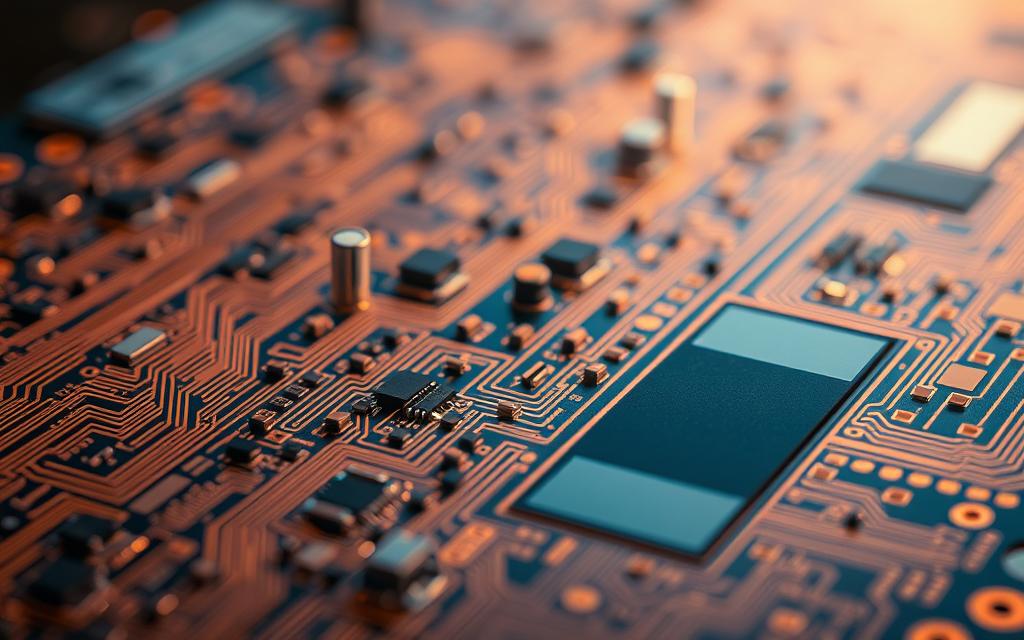

Essential PCB Components and Materials

Modern printed circuit boards use special materials and components. They need to be strong, conductive, and easy to make. This section looks at the key parts that make up a PCB.

Base Structural Elements

The base of any PCB is its substrate and conductive layers. The choice of material affects how flexible, heat-resistant, and good at carrying signals it is.

Substrate materials: FR-4 vs polyimide

FR-4 is the go-to for rigid boards. It’s strong and doesn’t catch fire easily. It’s perfect for most gadgets. Polyimide is used for flexible circuits. It can handle very high temperatures, making it great for cars and planes.

| Property | FR-4 | Polyimide |

|---|---|---|

| Flexibility | Rigid | Flexible |

| Max Temp | 130°C | 260°C |

| Cost | £ | £££ |

Copper foil types and weights

Electrodeposited copper (ED) makes fine traces smooth. Rolled-annealed (RA) foil is more flexible. Common weights are:

- ½ oz (18µm) for high-density designs

- 1 oz (35µm) for standard power handling

- 2 oz (70µm) in high-current applications

Critical Functional Layers

Specialised layers are needed for precise electrical performance and protection.

Conductive pathways etching process

Photolithography creates circuit patterns by:

- Applying UV-sensitive photoresist

- Exposing through a patterned mask

- Chemical etching of unwanted copper

Solder mask composition and colour variations

Epoxy-based solder masks stop short circuits and let soldering happen. Green is common, but modern boards use:

- Red for high-visibility prototypes

- Blue in gaming hardware

- Black in premium consumer devices

Silkscreen labelling requirements

White epoxy ink marks components and shows polarity. Standards require:

- Legible text ≥0.8mm height

- Clear polarity indicators

- Reference designators matching schematics

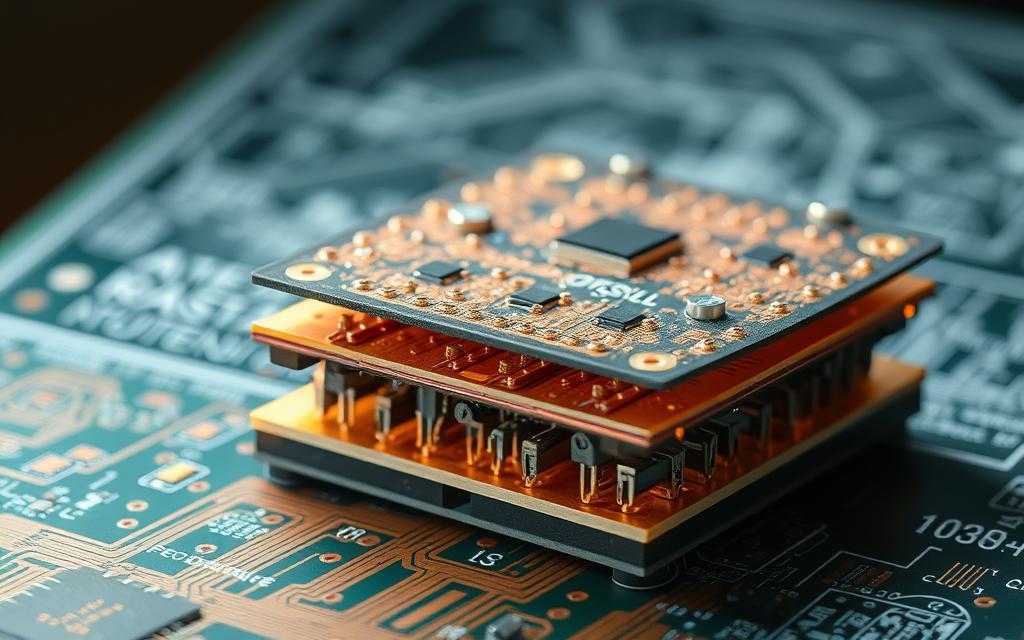

Advanced Component Integration

Modern electronics need new ways to mount complex parts.

Through-hole vs surface-mount components

Through-hole technology (THT) is good for repairs and reliability. Surface-mount devices (SMD) fit automated assembly of small designs.

Ball grid array (BGA) packaging

BGA packaging uses solder balls under chips. It increases pin density by 50% over QFP packages. This is key for modern chips and FPGAs.

High-density interconnect (HDI) features

HDI PCBs use microvias and buried traces. They’re great for 5G routers and wearable tech. Key features include:

- Blind/buried vias ≤150µm diameter

- Stacked via configurations

- Thin dielectric layers (≤50µm)

PCB Manufacturing Process Breakdown

Modern PCB making uses precise engineering and strict quality checks. It turns digital designs into working circuit boards. This process has three main steps, each needing special skills and the latest tech.

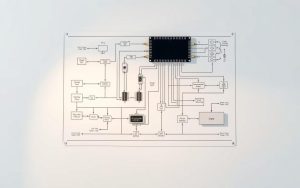

Design and Prototyping Phase

Designers start with CAD software like OrCAD or Altium Designer. They make detailed diagrams. These tools help place components correctly and check electrical rules.

Design for Manufacturability (DFM) Checks

DFM checks spot problems before making prototypes. They look at:

- Minimum trace width verification

- Drill hole alignment tolerances

- Copper weight distribution analysis

Industrial Production Stages

After designs are checked, manufacturers start the production process. This needs very precise work.

Photolithography Process Steps

This method transfers patterns onto the board through chemical reactions:

| Stage | Process | Purpose |

|---|---|---|

| 1. Cleaning | Alkaline solution bath | Remove surface contaminants |

| 2. Lamination | Dry film resist application | Create UV-sensitive layer |

| 3. Exposure | UV light through photomask | Transfer circuit pattern |

Chemical Etching Precision Controls

Ferric chloride solutions remove copper with up to ±0.025mm accuracy. The etching baths are kept at 45-55°C for best results.

Automated Optical Inspection (AOI) Systems

High-resolution cameras check boards for defects like:

- Incomplete traces

- Solder mask irregularities

- Component misalignment

Quality Assurance Protocols

Final checks make sure boards work well in different fields.

IPC-A-600 Acceptance Criteria

This global standard sets rules for:

- Solder joint integrity

- Conductor spacing

- Substrate delamination resistance

Environmental Stress Testing Methods

Aerospace-grade boards face 500+ thermal cycles. This checks how they perform in extreme temperatures.

Cross-Section Analysis Techniques

Microscopic checks look at plated through-holes for:

- Copper distribution uniformity

- Interconnect voiding

- Layer alignment accuracy

Contemporary Applications and Future Directions

Printed circuit boards are changing fast, meeting today’s needs and looking to the future. They help us connect quickly and power important medical devices. This shows how versatile PCBs are in many areas.

Current Industry Implementations

Three main areas are pushing PCB technology forward with their unique needs:

5G network infrastructure demands

5G PCBs use special materials to handle fast data. They help base stations work better, making data speeds very high.

Electric vehicle power systems

PCBs in EVs manage battery health. They can handle lots of cells and tough conditions.

Medical imaging equipment requirements

MRI machines use special PCBs to avoid interference. This helps find small tumours.

Emerging Technological Frontiers

New ways are changing how PCBs are made:

3D-printed electronics integration

A new method prints antennas on curved surfaces. It makes IoT devices smaller and simpler.

Biodegradable substrate research

Scientists at Cambridge are working on biodegradable substrates. These boards break down in soil, helping reduce waste.

AI-optimised design trends

AI helps design PCBs for data centres. It makes them better and more efficient.

These changes are part of a bigger move towards green electronics. Our look at smart home PCBs shows how important this is. It’s a big step forward for the next decade.

Conclusion

Printed circuit boards are key to modern tech progress. They power everything from Apple’s smartphones to Tesla’s electric cars. They also help in making life-saving medical gear like MRI scanners and defibrillators.

PCBs are vital in new energy systems and space tech. SpaceX uses them for satellite and rocket control. As IoT and 5G grow, PCBs will keep playing a big role.

Now, making PCBs must be green. Samsung and Panasonic use eco-friendly materials and methods. AI helps make production better, cutting down waste and improving accuracy.

Engineers need to know PCB basics for new tech challenges. This includes better cooling and signal quality. As tech gets more complex, knowing PCBs is key.

PCB tech links ideas to reality. It’s used in everything from Arduino projects to Siemens automation. Its growth will help create smarter cities and better healthcare and energy systems.